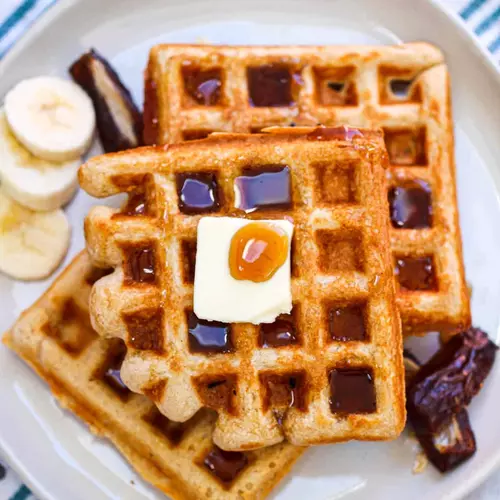

Today, bread baking has become not only the domain of bakeries, but also grocery stores, eateries, and even small eateries. You can prepare your own bread either thanks to deep-frozen products or thanks to the preparation of home-made dough. However, if you want to bake bread effectively, be it in a restaurant, shop or any gastronomic establishment, a bakery oven becomes indispensable.

It is an oven with an unusual structure and specialized applications, allowing you to bake any kind of bread, both from your own dough and from deep-frozen dough. Bakery ovens are different, we will tell you about their construction, functionality and application possibilities in this article.

GP | Bakery oven - structure and operation

The first baking ovens were built in antiquity, because since then man began to bake bread. Of course, modern ovens are significantly different from their predecessors, but already in the 19th century, baking ovens were created that can be considered the precursors of those known to us today.

The baking oven consists of the following modules:

- the bed or foundation of the oven, in the past, bakery ovens were wood or coal-fired, so they had to have a solid bed that could withstand high temperatures,

- heating channels that supplied heat to the so-called "heart of the baking oven", causing the dough to be thermally processed,

- working system - batch, called baking shaft, which received the load of dough for baking.

The above description is a brief description of a basic bakery oven, and in order to delve further into it, one would have to divide bakery ovens into types. Here, however, we distinguish:

- electrically powered furnaces,

- gas fired furnaces,

- wood or coal-fired furnaces.

Subsequent divisions result from the purpose, efficiency and capabilities of individual furnaces. However, the principle of operation of a bakery oven is the same in most cases. The heat distributed through the heating channels enables thermal processing of the dough, which results in a ready-made baking.

GP | Bakery oven - advantages and disadvantages depending on the type of oven

A bakery oven, like everything in professional gastronomy, has its advantages and disadvantages, depending on what type of oven it is.

Basic bakery ovens are electric, wood and coal-fired or gas-fired ovens. The most common are electric stoves, the advantages of which are:

- convenience of use due to universal access to electricity,

- ease of supplying such a furnace,

- easy to clean and maintain.

The disadvantages must be replaced, the higher costs resulting from the price of electricity and the need to connect a special power supply.

A wood-fired or coal-fired bakery oven is definitely cheaper to use, but requires the connection of flue gas ducts and ventilation ducts to ensure exhaust and ventilation. It is definitely a very efficient oven, in addition, many bakers claim that the best bread, the most tasty and aromatic, is made only in such an oven.

As for the gas oven, it is the most efficient and at the same time very clean. Its only disadvantage is the need to connect the gas installation and the chimney and ventilation systems. However, it is definitely a very efficient bakery oven, which is more and more often used in professional bakeries.

Baking oven gastroprodukt.pl