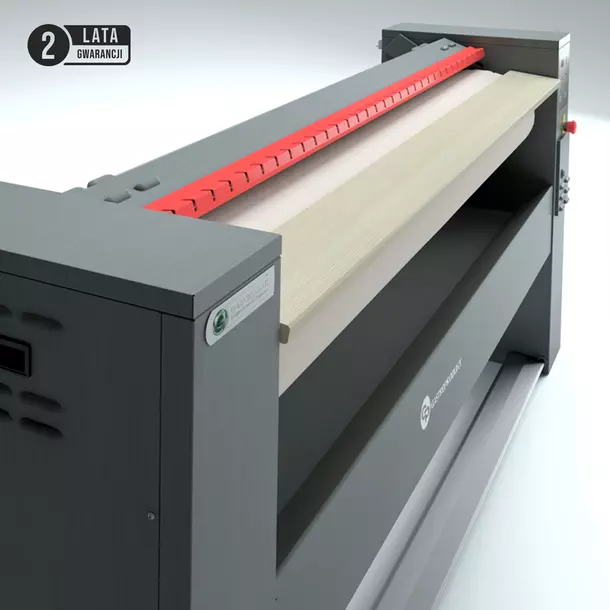

Rotary ironer Mod. 140/25 PREMIUM

The flatbed ironers are the perfect solution for restaurants, hotels, hospitals, etc., ensuring great work results.

The excellent quality of the materials used in our ironers - guarantees quick achievement of the desired temperature and allows it to be maintained along the entire length of the shaft.

Thanks to deep anodizing, it makes them hard and resistant to chemicals, eliminating corrosion problems (e.g. possible presence of chlorine residues or other elements in fabrics). Finally, the ceramic fiber insulation ensures maximum thermal efficiency and minimum heat loss to the surrounding environment, with significant advantages also for a more comfortable working environment.

The quality of ironing is also influenced by the thermal efficiency: our armored and sealed heating elements are integrated into the shaft, and not like in traditional devices - they are placed on the back. Finally, the type of roller also plays an important role: they have a perforated roller as standard | S160 / 30, S200 / 30 | with a suction motor, covered with a double layer of soft steel wool, cotton felt and an outer NOMEX® coating, which makes it suitable for ironing even flat linen with a humidity of 20-25%. Going even further, it is possible to make the cover of the roller of steel MAXPRESS® springs and NOMEX® felt, which enable ironing of linen with a humidity of 40-45%.

The presented ironers are single-headed, i.e. they can be placed against a wall and operated by a single operator. They are equipped with a roller speed control system (in inverter technology), which allows ironing of more damp linen or with very difficult creases, and a suction motor that, together with a perforated roller, is able to eliminate the steam generated during the ironing phase, improving the working environment and quality of ironing .

The ironers are equipped with the ST23 controller, which manages the temperature via P.I.D. system (proportional - derivative - integration). The system constantly modulates the power, optimizing consumption: even heat distribution, low consumption, no risk of overheating and, of course, excellent ironing quality.

- Dimensions: 1800x420x1005 (h) mm

- Roller length: 1400 mm

- Shaft diameter: 250 mm

- Ironer capacity: 40 kg /hour

- Feed speed: 3.9 m /min

- Power supply: 400V - 380-415V 3 ~ 50 /60Hz

- Total power: 7.18kW

- Weight: 145 kg

* Device designed for continuous operation.