Laundry room with a soul - Check how simple it is

New possibilities, perfect performance as always is the GWM / GWN Wavy Line. The new Wavy control system is an easy-to-use, interactive touchscreen user interface that provides the visual information needed to program and monitor our washers. Inspired by the world of high technology, Wavy uses the potential of the application language to make your daily laundry work easier and faster. The procedures are simple - step by step: it is a control system that speaks the same language as the operator and adapts to his level of experience.

It is an ideal solution for people requiring professional quality: Hotels, DPS, Meat, Dairy, Fire Department etc. GWM Wavy medium and low spin washing machines consist of a one-piece frame that is not subject to movement or damage: wear and mechanical stresses are reduced to a minimum thanks to the lower spin speed (200 G and 100 G) and the presence of a stiff, non-deformable frame instead of springs and shock absorbers. This results in a longer service life, reduced maintenance costs and low noise levels

The GWM and GWN Wavy come standard with the patented DWS precision weighing system, which uses the Wavy control to calculate the exact amount of energy, water and detergent needed based on the actual amount of laundry loaded. In this way, the device adapts with extreme precision to every slightest change in load. GWM and GWN Wavy washing machines with medium and low spin speed are not only energy-saving, but also environmentally friendly, as they guarantee 97% recycling of the machine

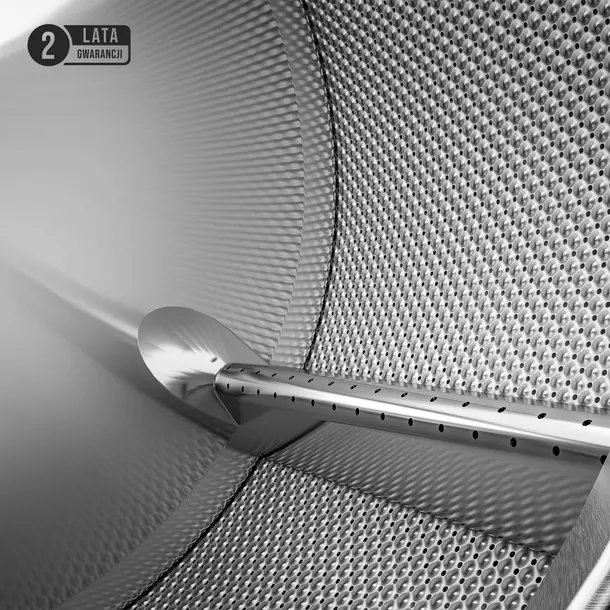

Equipment has a low environmental impact not only during its "life cycle" but also when you choose to change it. There are numerous micro-holes (about 8%) in the drum, which guarantees a quick flow of water. The entire drum is made of AISI304 stainless steel with a hemispherical structure that ensures gentle contact with the material, without unnecessary creases.

The devices are also equipped with a steel drum with a special hemispherical structure, which ensures a gentle touch of the fabric and prevents water from reflecting off the drum during spinning. These machines, characterized by a stiff, solid and solid frame, do not need springs or shock absorbers as only the drum moves. This means less wear and maintenance, as well as excellent silence. Due to their anchoring to the ground, these rigid washing machines are also perfect for use on decks of small and medium-sized ships, ferries and cargo ships. Ergonomically placed and equipped with a dual inlet for cold or hot water, the 4-compartment dispenser can be used with powder or liquid detergent: the correct water flow is always ensured according to the set washing temperature.

Since each washing phase requires a specific type of water, the washing machine has three inputs: warm, cold, soft and hard.

All models mix the three types independently and automatically.

Present on all Grandimpianti models, the MIXER mixes water and detergents before they enter the drum and come into contact with the garment, thus preventing damage or discoloration.

Finally, a 3 ”(76 mm) diameter motorized drain valve is located on the front of the unit for quick and easy maintenance. Extremely low noise level <65 dB during operation.

The washing machine door opens to 180 degrees, allows easy unloading of the laundry.

The devices have 20 standard programs that can be personalized.

* Detergent pumps can be installed!

- Drum volume 180 L

- Drum diameter 460 mm

- Capacity kg 9 ÷ 18 (1: 10) *

- Net dimensions (mm): 970 ÷ 940 ÷ 1460 (h)

- Net weight ÷ Gross weight (kg) 270 ÷ 280

- Spin: 1165/400 (rpm) G-factor

- Speed: 20 ÷ 60/1075 rpm

- Power: 380-415V 3N 50 /60Hz6

- Power: 18 kW

- Humidity level after spinning: 43-47%

GP | Industrial dryer for laundry WAVY 18kg | GP.GD450

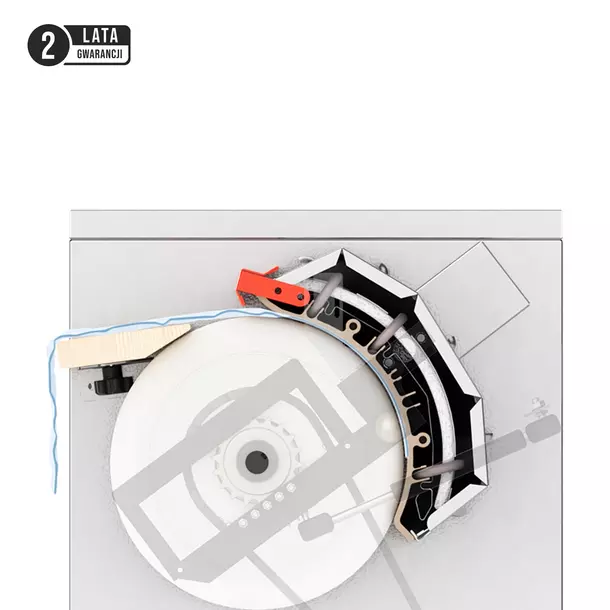

Changing the rotation of the drum with an inverter, the rotational speed of the drum is managed by a geared motor which uses inverter technology to regulate the speed, i.e. allows a so-called "soft start"

Drum speed is automatically adjusted to the actual washing moisture content

Thanks to the "WAVY System" i.e. temperature control, big savings are achieved in each cycle (about 12 min)

10 programs are installed as standard, it is also possible to electronically set up to 35 programs

Free editing of parameters at work by the dryer operator even during the running cycle

There is also a humidity sensor that allows drying without wasting time and energy. The drying program ends when the laundry is actually ready

Drum and air ducts are thermally insulated (such as in ovens) to reduce heat loss so that we can achieve faster drying results with minimum consumption

- Payload capacity: 18 kg

- Drum dimensions: 761x660 | 450dm3

- Door dimensions: 612mm

- Drum speed: 40 /(20:60) rpm

- Dimensions: 970x990x1810 (h) mm

- Evaporation (l /h): 12.55

- Cycle duration: 40 min

- Gross weight: 302kg

- Consumption: 17.4kW

- Motor power 0,75kW

- Total power: 31,3kW

- Power supply: V 400/3 + N (380-415 /3 + N) 50Hz /60Hz

- Noise level: <60 (dB )

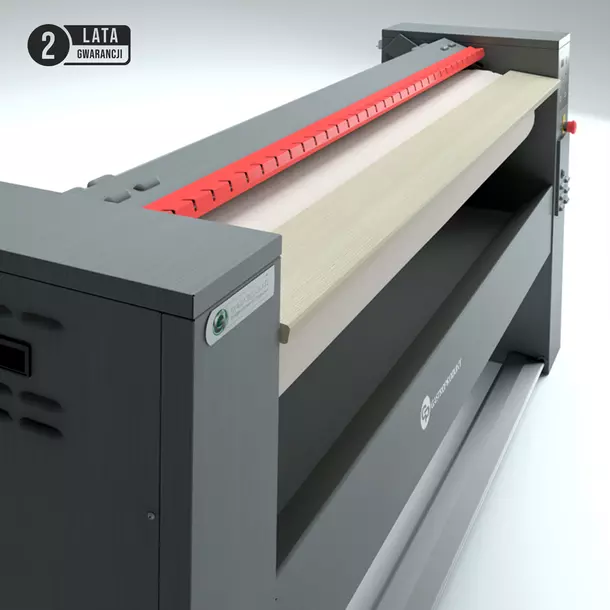

GP | Industrial electric pan mangle | Mod. 160/30 | PREMIUM

The flatbed ironers are the perfect solution for restaurants, hotels, hospitals, etc., ensuring great work results.

The excellent quality of the materials used in our ironers - guarantees quick achievement of the desired temperature and allows it to be maintained along the entire length of the shaft.

Thanks to deep anodizing, it makes them hard and resistant to chemicals, eliminating corrosion problems (e.g. possible presence of chlorine residues or other elements in fabrics). Finally, the ceramic fiber insulation ensures maximum thermal efficiency and minimum heat loss to the surrounding environment, with significant advantages also for a more comfortable working environment.

The quality of ironing is also influenced by the thermal efficiency: our armored and sealed heating elements are integrated into the shaft, and not like in traditional devices - they are placed on the back. Finally, the type of roller also plays an important role: they have a perforated roller as standard | S160 / 30, S200 / 30 | with a suction motor, covered with a double layer of soft steel wool, cotton felt and an outer NOMEX® coating, which makes it suitable for ironing even flat linen with a humidity of 20-25%. Going even further, it is possible to make the cover of the roller of steel MAXPRESS® springs and NOMEX® felt, which enable ironing of linen with a humidity of 40-45%.

The presented ironers are single-headed, i.e. they can be placed against a wall and operated by a single operator. They are equipped with a roller speed control system (in inverter technology), which allows ironing of more damp linen or with very difficult creases, and a suction motor that, together with a perforated roller, is able to eliminate the steam generated during the ironing phase, improving the working environment and quality of ironing .

The ironers are equipped with the ST23 controller, which manages the temperature via P.I.D. system (proportional - derivative - integration). The system constantly modulates the power, optimizing consumption: even heat distribution, low consumption, no risk of overheating and, of course, excellent ironing quality.

GastroProdukt Professional | Professional flat iron GP 160/300 PREMIUM

- They are the perfect solution for restaurants, hotels, hospitals etc. ensuring perfect results.

- The heating elements are resistant to moisture and placed directly on the ironing plate.

- Safety thermostat prevents overheating

- Electronic control unit that monitors all the parameters of the ironer and optimizes energy consumption

- Roller speed control - option ( model.160 /30AV )

- Dimensions: 2200x500x1100 (h) mm

- Shaft length: 1600 mm

- Shaft diameter: 300mm

- Ironer capacity: 50 kg /hour

- Feed speed: 3.9 m /min

- Power supply: 400V - 380-415V 3 ~ 50 /60Hz

- Noise: 45 dB

- Total power: 13.6kW

- Weight: 299 kg

* Device designed for continuous operation.