In 2007, Slayer set itself the goal of creating an espresso machine that would be out of the box, regardless of the cost of such an endeavor. After two years of work on the project, we shook the industry with a revolutionary method of extracting espresso. Today, our flagship product uses innovative technology, guaranteeing an unparalleled drinking experience with every cup of coffee.

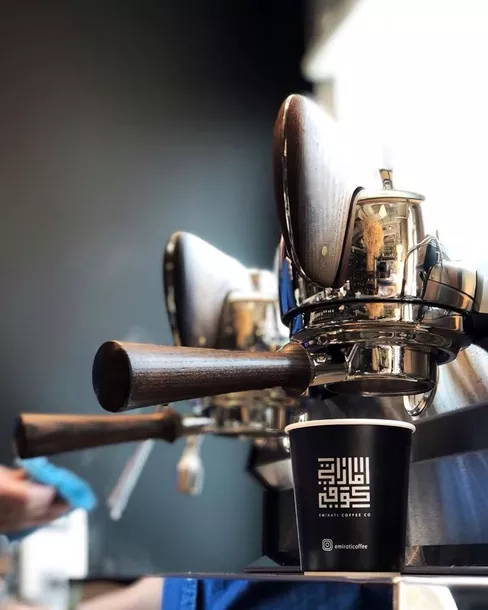

Slayer Espresso opens the door to taste profiling. The patented flow control made possible by a precise needle valve allows you to make changes and modifications to the taste of your espresso. In the hands of a professional barista, the brew activator becomes the basic tool that gives you the chance to discover the best of each coffee.

Extraction starts during the initial infusion, the slow humidification phase, during which the flow rate is severely limited. As soon as the coffee layer is completely saturated, the flow is increased when the brewing option is turned on, and pressure is built up at the same time. Both the described positions of the activator are used with different intensity, according to various patterns, thanks to which it is possible to achieve the desired balance of coffee flavor. This manual brewing technique leads to a real and perceptible change in taste and aroma. it is not just an engineering trick.

The slow impregnation also offers the possibility of proper extraction with extremely favorable grinding settings. Maker Slayer – thanks to the pre-infusion option – allows, and even prefers, the use of particles of various sizes, which cannot be used in any other device of this type.

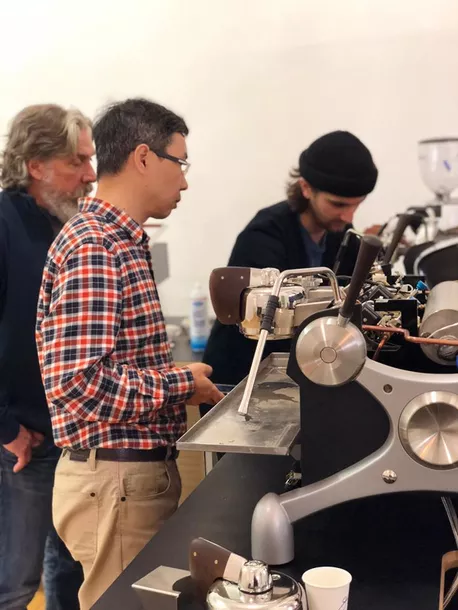

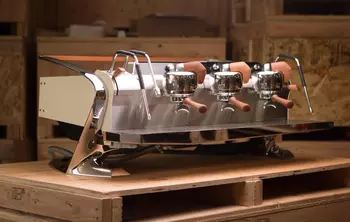

Some types of equipment or fittings are intentionally made invisible or out of sight, but the coffee machine is quite the opposite – is like a stage star. Slayer invites all baristas to participate in the performance of preparing coffee for your customers. Hand-made elements and personalized functions of the coffee machine allow for the cooperation of a man with a coffee making machine, which results in unforgettable impressions on both sides of the counter.

Today, our flagship product uses innovative technology, guaranteeing you an unparalleled experience while drinking every cup of coffee.

Professional Tool!

Our coffee machine was created to meet the highest requirements, its potential is used by the best baristas in the world. The unlimited steam options, unwavering temperature stability and the revolutionary control of the extraction process make us proud to consider the Slayer Espresso machine as a pillar of our brand.

A one-of-a-kind experience provided by the Slayer – unequaled in operation and durability. Independent brewing groups, enormous steam power and initial brewing boilers not available in other devices – all controlled by digital technology – make up the most efficient coffee machine on the market. The temperature is configured and maintained at an appropriate level using specially designed mechanisms that allow for multi-level extraction and stability in the production of steam. Slayer lives up to its promise to provide unlimited steam.

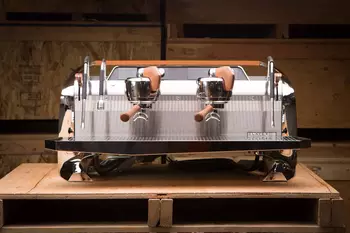

Thanks to the flavor profiling possibilities offered by Slayer Espresso , the coffee preparation process becomes a completely new experience. Each of the 3 brewing groups can be set to a specific temperature and flow rate to optimize the extraction process for all types of coffee. Patented technology introduces the initial brewing phase as well as extraordinary brewing options for endless possibilities for a great espresso.

Product characteristics

- Manual espresso extraction

- Moisturizing phase – initial brewing

- Taste profiling with activator with 3 items to choose from

- Patented flow rate control

- Solenoid groups

- Independent brew boilers

- Unlimited steam

- Initial brew boiler

- Digital temperature control

- Handles and activators made of ash

- Mixing content with hot water

- Modular timers for the pre-infusion phase

- Universal power

- Mirror rail base, in which the cup is visible

- Made in Seattlle in USA

- Certified with ETL Sanitation * safety (NSF /ANSI standard 4 compliant)

Highlights:

In the base package:

- Brew groups for 1 million brewing cycles prior to review

- Flask without spout (naked portafilter), chrome plated, brass

- 58mm portafilter strainer

- Teflon-coated shower heads for easy cleaning

- PID controller to control the brewing temperature to ensure accuracy down to -17

- PID Love controller for steam and initial brewing for quick changes

- 1.3 mm 4 hole steam nozzle ends

- Saturated brew groups with automatic bleeding

- External rotary pump

- Direct hydraulic connection only

- Certified with ETL Sanitation * safety (NSF /ANSI standard 4 compliant)

In the Enhanced Package:

- Initial brewing timers

- Tap with hot water

- Selection of the end of the steam nozzle

- Single or double outlet

- Lowered drip tray for tall cups

Boilers :

- Steam boiler: 7.4 liters

- Brew boiler: 1.2 liters per group (2)

- Initial brewing boiler: 3.3 liters

Power and Electricity:

- 200-260 V, AC, 50/60 Hz

- Single-phase system (optional three-phase)

- 6300 W

- 27 A

- NEMA 6-50 plug socket (included)

Installation requirements:

Blat:

- Minimum load: 100 kg

- Two (2) power /water /drain holes: 5 centimeter diameter

Hydraulic:

- Water distribution pipes: dedicated 3/8 inch BSP pipes, cold water with shut-off valve *

- Water supply pressure: 3-5 barów /43-72 PSI

- Feed water flow rate: 1.5 gallons (68.19 liters) per minute

- Drain: open line drain located within 1.2 meters

Dimensions :

- Length: 77.5 cm

- Width: 67.5 cm

- Height: 43.5 cm

- Weight 100 kg

Water quality:

- Solid Dissolved Compounds (TDS): 75-125 ppm (0.75-1.25 mmol /l)

- Hardness: not exceeding 50 ppm (0.5 mmol /l)

- Use a 3/8 in. compression fitting for 3/8 in. NPT male threaded pipe and thread to 3/8 in. BSP drain

- A water filter is mandatory !!!